Water and Environment

At Prinzhorn Group, we see water stewardship as an essential part of our environmental responsibility. Reducing consumption, improving treatment, and protecting the ecosystems around our sites are at the heart of our approach. Every drop we save and every litre we return cleaner than before strengthens our commitment to nature.

In 2024, we enhanced our water management strategy with more precise monitoring and site-specific reduction targets. Across our paper mills, closed-loop systems and advanced filtration technologies now allow process water to be reused multiple times before discharge, significantly lowering overall consumption.

One highlight was the commissioning of a modern water treatment plant in Spremberg, capable of processing over 15,000 cubic metres per day and returning water to the environment in better condition than when it entered. Similar upgrades are planned at other sites, with a focus on removing even microscopic pollutants. Our recycling operations are also strengthening stormwater management to protect local waterways from contamination.

Water protection goes hand in hand with biodiversity preservation. Around our facilities, we are creating green buffer zones, planting native trees, and restoring natural habitats. In Hungary, a dedicated biodiversity project transformed former industrial land into a thriving wetland, providing a refuge for rare species.

Beyond water, we are implementing measures to safeguard air quality, maintain healthy soils, and ensure the responsible handling of chemicals. These actions help us meet the highest environmental standards while supporting local communities.

Looking ahead, every site will develop an annual action plan for water and environmental protection, supported by targeted investments in technology and infrastructure. Through innovation, responsibility, and collaboration, we aim to preserve natural resources for generations to come.

Science Based Targets Validated – A Milestone on Our Decarbonization Journey

At Prinzhorn Group, “We live circularity” defines how we operate and grow. Building on our circular business model, we are taking decisive, group-wide action to reduce our carbon footprint and lead the transition toward a low-carbon future.

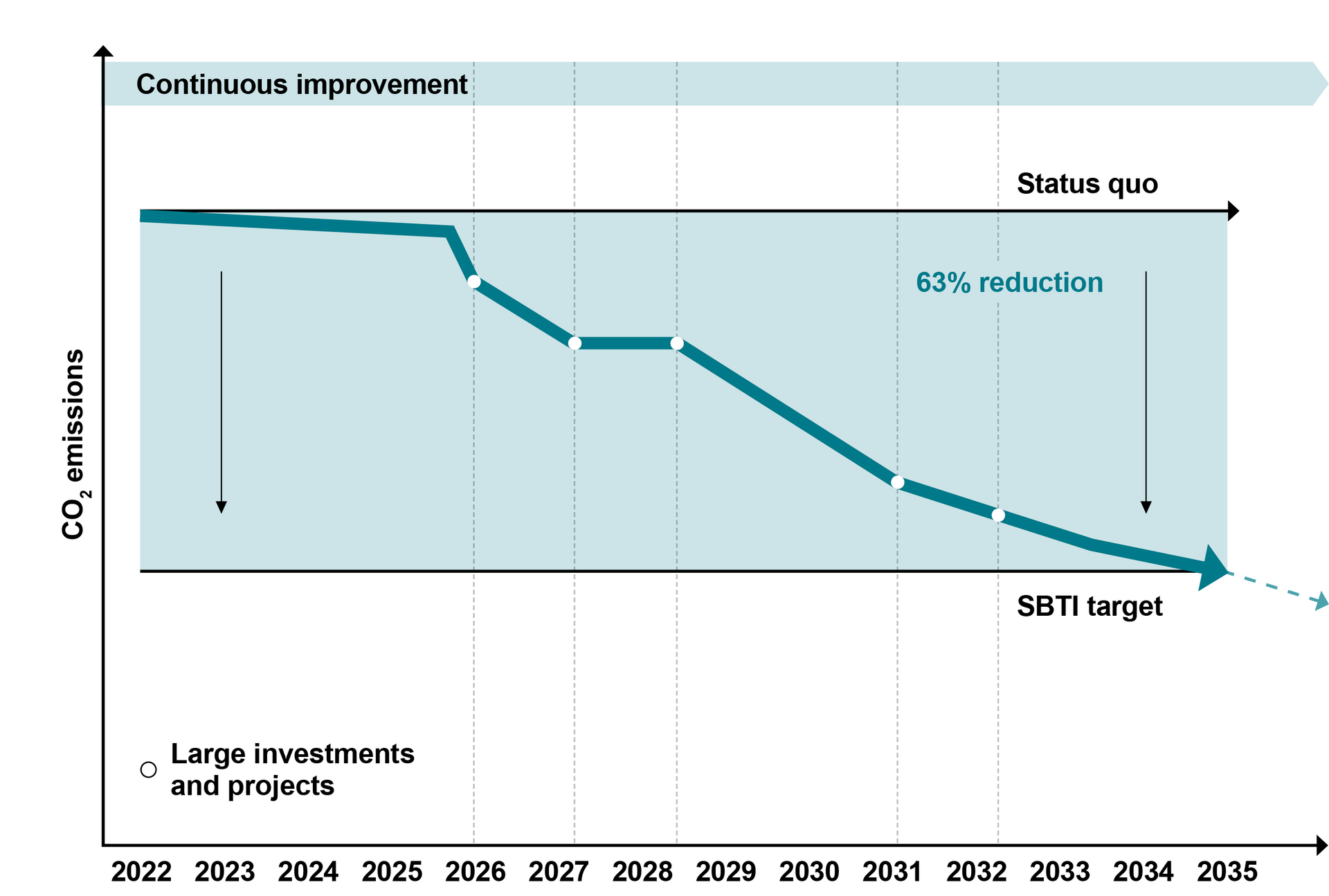

Our 2035 Targets

- Cut Scope 1 & 2 emissions by over 60% in our own operations

- Cut Scope 3 emissions by almost 40% across the supply chain

These goals align our business with global climate objectives. Between 2023 and 2026, we are investing €265 million in decarbonization projects across all divisions.

Four Focus Areas for Decarbonization

- Expanding renewable energy and own energy generation

- Driving energy efficiency and circularity

- Advancing low-carbon technologies such as RDF/W2F (Spremberg), CHP (Pitten, Austria), heat pumps, and biogas production

- Greening energy procurement group-wide

Circularity and Collaboration along the Supply Chain

Circularity remains central to our sustainability journey. We enhance material efficiency and product design, creating optimized, right-sized, and stackable packaging that saves resources without sacrificing performance. Our progress also depends on strong collaboration – with suppliers, customers, and partners. Together we reduce emissions across the value chain through responsible sourcing, low-carbon logistics, and joint innovation.

Sustainability as a Driver of Innovation

Achieving SBTi validation strengthens sustainability as a core driver of innovation and competitiveness. Alongside our 100% recyclability and 97% share of recycled key raw materials, our decarbonization roadmap positions us as a trusted partner for those who share our vision of a sustainable, circular future.